壓(ya)(ya)力除了能夠對溶質(zhi)(zhi)平(ping)衡(heng)分(fen)配系數(shu)、擴散系數(shu)以(yi)及液(ye)相線斜(xie)率等參(can)數(shu)產生影響以(yi)外(wai),還能改(gai)變(bian)影響溶質(zhi)(zhi)長程(cheng)傳質(zhi)(zhi)的(de)冷卻速率、等軸晶(jing)形核以(yi)及沉積(ji)等,從(cong)而影響鑄錠溶質(zhi)(zhi)分(fen)布的(de)均勻(yun)性,即宏/微(wei)觀偏析;如(ru)結合平(ping)衡(heng)分(fen)配系數(shu)和形核吉布斯(si)自由能隨壓(ya)(ya)力的(de)變(bian)化規律,加壓(ya)(ya)會抑制(zhi)枝(zhi)(zhi)晶(jing)沿壓(ya)(ya)力梯度方(fang)向的(de)生長,從(cong)而導致枝(zhi)(zhi)晶(jing)組織和微(wei)觀偏析呈現方(fang)向性等。

王書(shu)桓等(deng)71利(li)用(yong)高(gao)(gao)溫高(gao)(gao)壓(ya)反(fan)應(ying)釜(fu)研(yan)究了(le)壓(ya)力對于(yu)CrN12高(gao)(gao)氮鋼凝固(gu)過程中(zhong)偏(pian)析現象(xiang)。他們利(li)用(yong)LECO-TC600氮氧儀測量了(le)CrN12鑄錠上從中(zhong)心到(dao)邊部處(chu)試樣(yang)中(zhong)的氮含量,取樣(yang)位置如圖2-71所示。

王書桓等研究了1.0MPa、1.2MPa、1.4MPa和1.6MPa壓力(li)(li)(li)(li)下的(de)(de)(de)氮(dan)(dan)(dan)偏(pian)析(xi)(xi)(圖2-72).對比不同壓力(li)(li)(li)(li)下的(de)(de)(de)結果,可以發現(xian)1MPa下鑄(zhu)(zhu)錠(ding)(ding)內部氮(dan)(dan)(dan)偏(pian)析(xi)(xi)嚴(yan)重,隨(sui)著(zhu)壓力(li)(li)(li)(li)的(de)(de)(de)提(ti)高(gao),氮(dan)(dan)(dan)宏(hong)觀(guan)偏(pian)析(xi)(xi)得到(dao)了很大改(gai)善(shan)。當壓力(li)(li)(li)(li)提(ti)高(gao)到(dao)1.6MPa時,氮(dan)(dan)(dan)的(de)(de)(de)偏(pian)析(xi)(xi)程度明顯(xian)小于1.0MPa和1.2MPa下凝固的(de)(de)(de)鑄(zhu)(zhu)錠(ding)(ding),各部位(wei)氮(dan)(dan)(dan)含(han)量(liang)在0.360%左右,表(biao)明增大壓力(li)(li)(li)(li)提(ti)高(gao)了氮(dan)(dan)(dan)的(de)(de)(de)飽和溶解度。因(yin)此,在凝固過(guo)程中提(ti)高(gao)氮(dan)(dan)(dan)氣(qi)壓力(li)(li)(li)(li)可以對氮(dan)(dan)(dan)的(de)(de)(de)析(xi)(xi)出起到(dao)抑制作用(yong),對氮(dan)(dan)(dan)由固相(xiang)到(dao)液相(xiang)的(de)(de)(de)傳質起到(dao)阻礙作用(yong),使整個鑄(zhu)(zhu)錠(ding)(ding)中氮(dan)(dan)(dan)的(de)(de)(de)分壓趨于均勻,從而(er)減輕氮(dan)(dan)(dan)的(de)(de)(de)宏(hong)觀(guan)偏(pian)析(xi)(xi)。

1. 形核(he)率

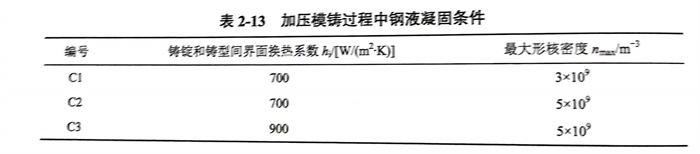

根據 Beckerman等的(de)(de)(de)研究(jiu)報道,在(zai)元(yuan)素(su)偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)的(de)(de)(de)模擬(ni)過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)中(zhong),由于各(ge)元(yuan)素(su)的(de)(de)(de)溶(rong)質分(fen)配系(xi)(xi)(xi)數(shu)均小于1,其(qi)偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)的(de)(de)(de)形成過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)和(he)最終偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)類(lei)型(xing)均相(xiang)似。因此,在(zai)偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)形成規(gui)律和(he)類(lei)型(xing)的(de)(de)(de)預測過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)中(zhong),可(ke)對合金(jin)體(ti)系(xi)(xi)(xi)進行簡化,選取(qu)主要合金(jin)元(yuan)素(su)進行偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)的(de)(de)(de)模擬(ni)。以(yi)19Cr14Mn0.9N 含(han)氮(dan)奧(ao)氏體(ti)不銹(xiu)鋼凝(ning)(ning)固(gu)過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)為(wei)(wei)例(li),其(qi)鐵(tie)素(su)體(ti)相(xiang)8存在(zai)區間(jian)較(jiao)窄,結(jie)合Wu等在(zai)多相(xiang)和(he)單(dan)相(xiang)偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)的(de)(de)(de)模擬(ni)研究(jiu)。可(ke)將該(gai)凝(ning)(ning)固(gu)過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)簡化為(wei)(wei)單(dan)相(xiang)凝(ning)(ning)固(gu)。氮(dan)作為(wei)(wei)含(han)氮(dan)鋼的(de)(de)(de)特征(zheng)元(yuan)素(su),其(qi)溶(rong)質分(fen)配系(xi)(xi)(xi)數(shu)較(jiao)小,偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)較(jiao)嚴(yan)重,在(zai)壓力(li)對19Cr14Mn0.9N含(han)氮(dan)鋼偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)影(ying)響(xiang)(xiang)的(de)(de)(de)分(fen)析(xi)(xi)(xi)(xi)(xi)過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)中(zhong),可(ke)將氮(dan)作為(wei)(wei)主要元(yuan)素(su),且忽(hu)略其(qi)他元(yuan)素(su)偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)對凝(ning)(ning)固(gu)過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)的(de)(de)(de)影(ying)響(xiang)(xiang)。基于壓力(li)對凝(ning)(ning)固(gu)過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)中(zhong)的(de)(de)(de)熱(re)(re)力(li)學參數(shu)、動力(li)學參數(shu)以(yi)及(ji)界面換(huan)熱(re)(re)系(xi)(xi)(xi)數(shu)的(de)(de)(de)影(ying)響(xiang)(xiang)規(gui)律,對三(san)種情況下 19Cr14Mn0.9N含(han)氮(dan)鋼的(de)(de)(de)凝(ning)(ning)固(gu)過(guo)(guo)(guo)程(cheng)(cheng)(cheng)(cheng)進行模擬(ni)分(fen)析(xi)(xi)(xi)(xi)(xi),預測壓力(li)對偏(pian)(pian)析(xi)(xi)(xi)(xi)(xi)程(cheng)(cheng)(cheng)(cheng)度和(he)類(lei)型(xing)的(de)(de)(de)影(ying)響(xiang)(xiang)規(gui)律,三(san)種情況(C1、C2和(he)C3)的(de)(de)(de)參數(shu)設置(zhi)見(jian)表(biao)2-13。

凝(ning)固(gu)(gu)20s后,三種凝(ning)固(gu)(gu)條(tiao)件下(xia)的(de)柱(zhu)狀(zhuang)晶(jing)(jing)(jing)(jing)一(yi)(yi)次(ci)枝(zhi)晶(jing)(jing)(jing)(jing)尖端(duan)位置(TIP)、柱(zhu)狀(zhuang)晶(jing)(jing)(jing)(jing)和(he)等(deng)軸晶(jing)(jing)(jing)(jing)體積分(fen)數以及液相(xiang)和(he)等(deng)軸晶(jing)(jing)(jing)(jing)速(su)率(lv)(lv)分(fen)布(bu)情況如圖(tu)2-73所示。對比圖(tu)2-73(a)和(he)(b)可以看出,當(dang)等(deng)軸晶(jing)(jing)(jing)(jing)最(zui)大形核密度從(cong)3x10°m-3增(zeng)至(zhi)5x10°m-3時,柱(zhu)狀(zhuang)晶(jing)(jing)(jing)(jing)一(yi)(yi)次(ci)枝(zhi)晶(jing)(jing)(jing)(jing)尖端(duan)發生了(le)較為明顯(xian)的(de)變化,尤其是在鑄錠底部位置,且等(deng)軸晶(jing)(jing)(jing)(jing)最(zui)大體積分(fen)數由0.514增(zeng)至(zhi)0.618.此外,等(deng)軸晶(jing)(jing)(jing)(jing)和(he)液相(xiang)的(de)最(zui)大速(su)率(lv)(lv)增(zeng)加幅度較小,分(fen)別從(cong)0.01246m/s和(he)0.0075m/s增(zeng)至(zhi)0.01266m/s和(he)0.0078m/s.

在三種凝固條件下,鑄錠凝固結束后柱狀晶(jing)向等(deng)(deng)(deng)(deng)軸(zhou)晶(jing)轉(zhuan)(zhuan)變(columnar to equiaxed transition,CET)位(wei)置(zhi)如圖(tu)2-74所示。隨著等(deng)(deng)(deng)(deng)軸(zhou)晶(jing)最大形核密度的增(zeng)加(對比(bi)C1和C2),液(ye)相中(zhong)的等(deng)(deng)(deng)(deng)軸(zhou)晶(jing)形核速率加快(kuai),極大地縮(suo)短了柱狀晶(jing)前(qian)沿(yan)等(deng)(deng)(deng)(deng)軸(zhou)晶(jing)體積分數到達阻擋分數(0.49)的時(shi)間,進(jin)而(er)促進(jin)了CET轉(zhuan)(zhuan)變,擴(kuo)大了等(deng)(deng)(deng)(deng)軸(zhou)晶(jing)區域。

增(zeng)加(jia)(jia)(jia)壓(ya)力(li)(li)還能增(zeng)加(jia)(jia)(jia)等(deng)軸晶(jing)最大(da)形核(he)密度(du),從而(er)加(jia)(jia)(jia)劇(ju)偏(pian)(pian)(pian)析(xi)(xi)(xi)。凝固結束后氮(dan)的宏觀(guan)偏(pian)(pian)(pian)析(xi)(xi)(xi)如圖2-75所示。隨著等(deng)軸晶(jing)最大(da)形核(he)速率的增(zeng)加(jia)(jia)(jia),氮(dan)的宏觀(guan)偏(pian)(pian)(pian)析(xi)(xi)(xi)范(fan)圍(wei)C從-0.07~0.116 擴大(da)至-0.072~0.137,氮(dan)的宏觀(guan)偏(pian)(pian)(pian)析(xi)(xi)(xi)加(jia)(jia)(jia)劇(ju);此(ci)外,鑄錠底(di)部(bu)負偏(pian)(pian)(pian)析(xi)(xi)(xi)區域(yu)(yu)也隨之(zhi)增(zeng)大(da),鑄錠內部(bu)氮(dan)最大(da)偏(pian)(pian)(pian)析(xi)(xi)(xi)位置逐步(bu)向上(shang)移(yi)動。因此(ci),在增(zeng)加(jia)(jia)(jia)等(deng)軸晶(jing)最大(da)形核(he)密度(du)方面,增(zeng)加(jia)(jia)(jia)壓(ya)力(li)(li)能夠擴大(da)等(deng)軸晶(jing)區域(yu)(yu),從而(er)增(zeng)大(da)負偏(pian)(pian)(pian)析(xi)(xi)(xi)范(fan)圍(wei),提升氮(dan)最大(da)偏(pian)(pian)(pian)析(xi)(xi)(xi)位置的高度(du),以(yi)及加(jia)(jia)(jia)劇(ju)氮(dan)的宏觀(guan)偏(pian)(pian)(pian)析(xi)(xi)(xi)。

2. 強(qiang)化冷卻

增加(jia)(jia)(jia)壓力(li)可通過(guo)強化冷(leng)(leng)卻和擴(kuo)大(da)“溶質截(jie)留效應”減(jian)輕或(huo)者消除氮(dan)宏觀(guan)偏析(xi)。根(gen)據圖2-73(b)和(c)可知,在(zai)凝固(gu)20s時(shi),等(deng)(deng)(deng)軸晶(jing)(jing)的(de)(de)(de)沉積(ji)(ji)量隨(sui)(sui)著冷(leng)(leng)卻速率(lv)(lv)的(de)(de)(de)增大(da)而(er)增多,等(deng)(deng)(deng)軸晶(jing)(jing)最大(da)體積(ji)(ji)分數從0.618增加(jia)(jia)(jia)至0.692,等(deng)(deng)(deng)軸晶(jing)(jing)和液(ye)相(xiang)(xiang)的(de)(de)(de)最大(da)速率(lv)(lv)在(zai)C2凝固(gu)條件(jian)下(xia)分別為(wei)0.01266m/s和0.0078m/s,在(zai)C3凝固(gu)條件(jian)下(xia),分別為(wei)0.01221m/s和0.0074m/s.在(zai)同一(yi)時(shi)刻下(xia),隨(sui)(sui)著冷(leng)(leng)卻速率(lv)(lv)的(de)(de)(de)增大(da),等(deng)(deng)(deng)軸晶(jing)(jing)和液(ye)相(xiang)(xiang)的(de)(de)(de)最大(da)速率(lv)(lv)呈現出略微減(jian)小(xiao)的(de)(de)(de)原因是冷(leng)(leng)卻速率(lv)(lv)的(de)(de)(de)增大(da)加(jia)(jia)(jia)快了鑄錠的(de)(de)(de)凝固(gu)進(jin)程,增大(da)了柱狀晶(jing)(jing)區域[圖2-73(b)和(c)],從而(er)使殘(can)余液(ye)相(xiang)(xiang)的(de)(de)(de)冷(leng)(leng)卻速率(lv)(lv)減(jian)小(xiao),減(jian)小(xiao)了與液(ye)相(xiang)(xiang)溫度相(xiang)(xiang)關的(de)(de)(de)熱浮力(li),進(jin)而(er)液(ye)相(xiang)(xiang)流(liu)動(dong)的(de)(de)(de)驅動(dong)力(li)減(jian)小(xiao),降(jiang)低(di)了液(ye)相(xiang)(xiang)流(liu)動(dong)速度;另外,隨(sui)(sui)著液(ye)相(xiang)(xiang)流(liu)動(dong)速度的(de)(de)(de)降(jiang)低(di),等(deng)(deng)(deng)軸晶(jing)(jing)沉積(ji)(ji)的(de)(de)(de)阻力(li)增大(da),等(deng)(deng)(deng)軸晶(jing)(jing)流(liu)動(dong)速度隨(sui)(sui)之減(jian)小(xiao)。

從圖2-74可以看出(chu)(chu),隨著冷卻速率的增加,CET位置(zhi)有(you)向心移(yi)動(dong)且呈扁平化(hua)的趨(qu)勢(shi),與19Cr14Mn0.9N鑄(zhu)錠CET檢測實驗結果相一(yi)(yi)致,進一(yi)(yi)步證明(ming)本(ben)模(mo)型具(ju)有(you)較(jiao)好的準確性和可信度。等(deng)軸晶區形(xing)狀隨著CET轉(zhuan)變位置(zhi)的改變,也逐步呈現出(chu)(chu)扁平化(hua)和減小(xiao)的趨(qu)勢(shi),氮(dan)的宏(hong)觀(guan)偏(pian)析范圍由-0.072~0.137減少(shao)至-0.067~0.130,且氮(dan)最大偏(pian)析形(xing)成位置(zhi)向鑄(zhu)錠頂部移(yi)動(dong)(圖2-76).因此,從強化(hua)冷卻角度而言(yan),加壓(ya)有(you)助于抑(yi)制CET,減小(xiao)等(deng)軸晶區,緩解(jie)氮(dan)的宏(hong)觀(guan)偏(pian)析。

綜(zong)上所述,增(zeng)加壓(ya)力(li)通(tong)過提高等軸(zhou)晶最(zui)大形核密(mi)度和(he)強(qiang)化(hua)冷(leng)卻(que)對(dui)氮宏觀偏(pian)(pian)析(xi)(xi)產(chan)生(sheng)了截然相反的(de)影(ying)響,兩(liang)者對(dui)宏觀偏(pian)(pian)析(xi)(xi)的(de)綜(zong)合影(ying)響還(huan)需要進一步研(yan)究。此外,基(ji)于對(dui)凝固熱力(li)學和(he)動(dong)力(li)學以及(ji)換熱系數(shu)的(de)分(fen)析(xi)(xi),壓(ya)力(li)對(dui)宏觀偏(pian)(pian)析(xi)(xi)的(de)影(ying)響不局限于增(zeng)大形核率和(he)強(qiang)化(hua)冷(leng)卻(que)這(zhe)兩(liang)方面,還(huan)能對(dui)與宏觀偏(pian)(pian)析(xi)(xi)相關的(de)平衡分(fen)配系數(shu)和(he)擴散速率等參數(shu)產(chan)生(sheng)重要影(ying)響。因(yin)而,壓(ya)力(li)對(dui)宏觀偏(pian)(pian)析(xi)(xi)的(de)影(ying)響還(huan)需要進行更(geng)深(shen)入的(de)研(yan)究和(he)探討。