1Cr18Ni9是18-8型不銹鋼(gang)最古老的一個牌號。耐蝕性、冷成型性能與0Cr19Ni9相近,由于此鋼含碳量高,一般沒有δ-鐵素體且奧氏體穩定,因此,此鋼更適于低溫和無磁等用途。

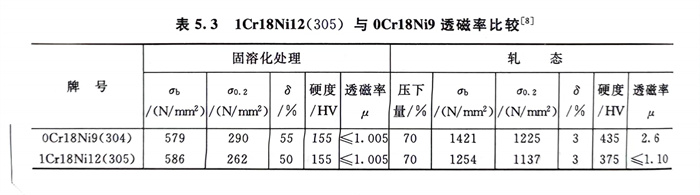

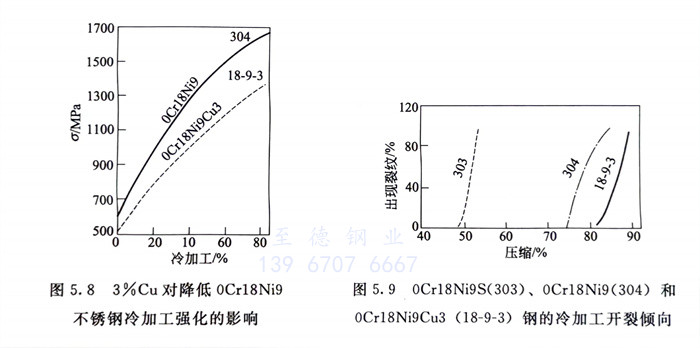

1Cr18Ni12和(he)0Cr18Ni9Cu3,前者(zhe)是通過提高1Cr18Ni9鋼的鎳含量,使奧氏(shi)體(ti)更(geng)(geng)(geng)加穩定(ding),經(jing)較大(da)(da)冷變形(xing)后,可基本上不產(chan)生馬氏(shi)體(ti)相變,既可使鋼的冷加工(gong)(gong)硬化傾向(xiang)(xiang)小,更(geng)(geng)(geng)易于(yu)(yu)冷加工(gong)(gong)成型,減少中(zhong)間(jian)退火次數。同(tong)時(shi),由于(yu)(yu)固溶態與軋態的透磁率變化很小(表5.3),較0Cr18Ni9(304)更(geng)(geng)(geng)適于(yu)(yu)無(wu)磁用途(tu)。而(er)0Cr18Ni9Cu3則系(xi)加入銅使奧氏(shi)體(ti)更(geng)(geng)(geng)加穩定(ding),冷加工(gong)(gong)過程轉變為馬氏(shi)體(ti)的敏(min)感性降低,從而(er)使鋼的冷作(zuo)硬化傾向(xiang)(xiang)和(he)冷作(zuo)速率以及冷開(kai)裂敏(min)感性下降,使此鋼在較小變形(xing)力作(zuo)用下可獲得最(zui)大(da)(da)的冷變形(xing),因此,0Cr18Ni9Cu3更(geng)(geng)(geng)適于(yu)(yu)緊(jin)固件和(he)深(shen)沖(chong)、深(shen)拉等(deng)用途(tu)。圖5.8和(he)圖5.9系(xi)一些試(shi)驗結果。

Y1Cr18Ni9是通(tong)過(guo)調(diao)整(zheng)鋼中P(≤0.20%)和S(≥0.15%)含量,而Y1Cr18Ni9Se則是通(tong)過(guo)調(diao)整(zheng)1Cr18Ni9 鋼中P(≤0.20%)和S(≥0.60% )并加入(ru)Se(≥0.15%),以使鋼具(ju)有(you)優良的冷切削加工性(xing)。