1. 坡口形式

由于受許用焊接電流的限制,這種焊接方法主要用于薄板的單層焊和中厚板多層焊的封底焊道,也可用于中厚板的焊接。在保證焊透的情況下,對接焊縫應力求縮小焊縫截面積,減少熔敷金屬并考慮操作方便,常用的坡口形式有V形、U形、雙面V形及V-U組合形等。奧氏體型不銹(xiu)鋼管(guan)子對接焊坡口形式見表4-26。

表4-26奧氏(shi)體型不銹鋼管子對接焊坡(po)口形(xing)式

各種接(jie)(jie)頭中T形接(jie)(jie)頭、對接(jie)(jie)接(jie)(jie)頭的保護效(xiao)果較好,而角接(jie)(jie)接(jie)(jie)頭、端接(jie)(jie)接(jie)(jie)頭因氣體流(liu)量分散性較大,保護效(xiao)果較差(cha),如圖(tu)4-35所示。

2. 焊前清理

焊接區及填充焊絲均(jun)應進行嚴格(ge)清(qing)理,清(qing)除(chu)氧化膜、油(you)污(wu)、臟物(wu)和水分等(deng)污(wu)物(wu)。

3. 焊接參數

a. 焊(han)接電流(liu)

根(gen)據焊(han)(han)件(jian)厚(hou)度(du)、接頭(tou)形(xing)式(shi)、焊(han)(han)接位置(zhi)等(deng)(deng)因(yin)素來(lai)選用焊(han)(han)接電(dian)流,除此還要考慮鎢極所承受電(dian)流的能力。焊(han)(han)接電(dian)流過大,容易產(chan)生燒穿(chuan)或使(shi)焊(han)(han)縫(feng)下陷和咬邊等(deng)(deng)缺陷,嚴(yan)重時(shi)還會引起鎢極燒損(sun)或產(chan)生夾(jia)鎢等(deng)(deng)缺陷。焊(han)(han)接電(dian)流過小(xiao),電(dian)弧燃(ran)燒不(bu)穩定,會造成(cheng)未焊(han)(han)透(tou)等(deng)(deng)缺欠。

b. 電(dian)弧電(dian)壓

主(zhu)要取(qu)決于(yu)焊接過程中(zhong)電(dian)(dian)(dian)弧(hu)的(de)(de)長度,電(dian)(dian)(dian)弧(hu)拉長、電(dian)(dian)(dian)弧(hu)電(dian)(dian)(dian)壓增(zeng)大,熔寬增(zeng)寬,熔深變淺。當電(dian)(dian)(dian)弧(hu)電(dian)(dian)(dian)壓過高時(shi),會導致焊接電(dian)(dian)(dian)弧(hu)不穩(wen),易產(chan)生(sheng)未(wei)焊透、未(wei)熔合(he)和熔池保(bao)護不佳等(deng)缺陷。應在保(bao)證電(dian)(dian)(dian)弧(hu)不短路(lu)的(de)(de)情況下(xia),盡(jin)量減少弧(hu)長,電(dian)(dian)(dian)弧(hu)電(dian)(dian)(dian)壓一般控(kong)制在9~20V范圍內,最常用的(de)(de)電(dian)(dian)(dian)弧(hu)電(dian)(dian)(dian)壓為(wei)9~14V。

c. 焊接(jie)速度

為了不破壞氣流對熔池的(de)(de)保護作用(yong),焊接(jie)(jie)(jie)(jie)(jie)速度(du)一般不宜過快(kuai)。在保證焊縫金屬(shu)和母材(cai)金屬(shu)不被氧(yang)化的(de)(de)前(qian)提(ti)下,為了提(ti)高(gao)生產(chan)效(xiao)率,盡(jin)可能提(ti)高(gao)焊接(jie)(jie)(jie)(jie)(jie)速度(du)。提(ti)高(gao)焊接(jie)(jie)(jie)(jie)(jie)速度(du),焊接(jie)(jie)(jie)(jie)(jie)接(jie)(jie)(jie)(jie)(jie)頭在450~850℃危險溫(wen)度(du)停留時間會相對減少,有利于提(ti)高(gao)焊接(jie)(jie)(jie)(jie)(jie)接(jie)(jie)(jie)(jie)(jie)頭的(de)(de)耐(nai)腐蝕(shi)性能。

d. 焊絲(si)

同一牌號的奧氏體不銹鋼(gang)焊接,焊絲的選擇見表4-27,不同牌號的奧氏體不銹鋼焊接,焊絲的選擇見表4-28。不銹鋼藥芯焊絲的選用見表2-28~表2-31。

我國的不銹(xiu)鋼(gang)藥(yao)芯焊(han)絲與AWS A5.22-1995《耐腐(fu)蝕(shi)鉻(ge)及(ji)(ji)鉻(ge)鎳鋼(gang)用藥(yao)芯焊(han)絲》及(ji)(ji)其(qi)他國家不銹(xiu)鋼(gang)藥(yao)芯焊(han)絲的對應關系,見表2-64。

e. 氬氣純度與流量

氬(ya)氣(qi)(qi)(qi)純度不低于99.9%(體(ti)(ti)積分數),氬(ya)氣(qi)(qi)(qi)純度愈高,保(bao)護效(xiao)果(guo)愈好。氣(qi)(qi)(qi)體(ti)(ti)流(liu)(liu)量(liang)(liang)過(guo)低,氣(qi)(qi)(qi)體(ti)(ti)挺度不足,排除周(zhou)圍(wei)空氣(qi)(qi)(qi)的(de)能(neng)力減弱,造(zao)成熔池保(bao)護效(xiao)果(guo)不佳;氣(qi)(qi)(qi)體(ti)(ti)流(liu)(liu)量(liang)(liang)過(guo)大,容易將熔池周(zhou)圍(wei)的(de)空氣(qi)(qi)(qi)卷入熔池,形成氣(qi)(qi)(qi)體(ti)(ti)紊(wen)流(liu)(liu),降低保(bao)護效(xiao)果(guo)。氬(ya)氣(qi)(qi)(qi)流(liu)(liu)量(liang)(liang)與噴嘴直徑(jing)大小有(you)關(guan),見(jian)式(4-6)。

氬(ya)氣流量不僅與噴嘴直徑有(you)關,還與焊接電(dian)流大(da)小有(you)關,它(ta)們之(zhi)間(jian)的參數(shu)選(xuan)擇見表4-29。

f. 電極極性(xing)

為了減少鎢(wu)(wu)極(ji)(ji)燒損(sun),延長鎢(wu)(wu)極(ji)(ji)壽命,一般(ban)采用直流電源(yuan)正(zheng)接(jie)(jie)(工件接(jie)(jie)電源(yuan)正(zheng)極(ji)(ji),鎢(wu)(wu)極(ji)(ji)接(jie)(jie)電源(yuan)負極(ji)(ji)。直流正(zheng)接(jie)(jie)在(zai)工藝文(wen)(wen)件上用符號DC或DCSP表示,DC是(shi)英(ying)文(wen)(wen)di-rect current 的縮寫(xie);DCSP 是(shi)英(ying)文(wen)(wen) direct current straight polarity的縮寫(xie)),也可以(yi)用交流鎢(wu)(wu)極(ji)(ji)氬弧焊機焊接(jie)(jie)奧氏體型(xing)不銹鋼。

g. 鎢極

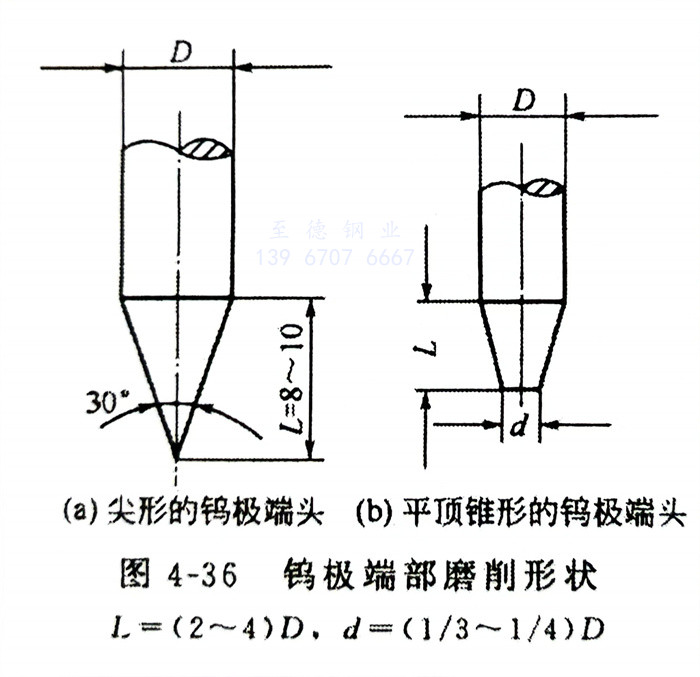

鎢(wu)(wu)(wu)(wu)極(ji)(ji)有純鎢(wu)(wu)(wu)(wu)極(ji)(ji)、釷鎢(wu)(wu)(wu)(wu)極(ji)(ji)和鈰(shi)鎢(wu)(wu)(wu)(wu)極(ji)(ji)3種,其中鈰(shi)鎢(wu)(wu)(wu)(wu)極(ji)(ji)(活化鎢(wu)(wu)(wu)(wu)極(ji)(ji))比純鎢(wu)(wu)(wu)(wu)極(ji)(ji)的工藝(yi)性(xing)好得多,且對人(ren)體損害小,推薦首(shou)選使用(yong)。鎢(wu)(wu)(wu)(wu)極(ji)(ji)直(zhi)徑(jing)與相應焊(han)(han)(han)接(jie)電(dian)(dian)源和極(ji)(ji)性(xing)條件下的焊(han)(han)(han)接(jie)電(dian)(dian)流允許值(zhi),參見表(biao)4-30、表(biao)4-31。施焊(han)(han)(han)前,要將(jiang)鎢(wu)(wu)(wu)(wu)極(ji)(ji)端(duan)(duan)部(bu)磨(mo)(mo)成一定形狀(zhuang),通常有尖(jian)頭和平(ping)頭等形狀(zhuang)。采用(yong)較(jiao)小的焊(han)(han)(han)接(jie)電(dian)(dian)流施焊(han)(han)(han)時,要選用(yong)小直(zhi)徑(jing)的鎢(wu)(wu)(wu)(wu)棒,端(duan)(duan)頭磨(mo)(mo)成尖(jian)頭形狀(zhuang),錐頂(ding)角(jiao)度(du)約30°,如(ru)圖4-36(a)所(suo)示。當(dang)采用(yong)大的焊(han)(han)(han)接(jie)電(dian)(dian)流施焊(han)(han)(han)時,鎢(wu)(wu)(wu)(wu)極(ji)(ji)應磨(mo)(mo)成帶(dai)有平(ping)頂(ding)的錐形形狀(zhuang),如(ru)圖4-36(b)所(suo)示。平(ping)頂(ding)錐形的端(duan)(duan)頭可避免尖(jian)端(duan)(duan)過熱熔化,減少鎢(wu)(wu)(wu)(wu)極(ji)(ji)端(duan)(duan)部(bu)損耗(hao),同(tong)時還有利于(yu)防止陰極(ji)(ji)斑點(dian)的游動,從而穩(wen)定電(dian)(dian)弧。鎢(wu)(wu)(wu)(wu)極(ji)(ji)端(duan)(duan)頭愈(yu)尖(jian)愈(yu)易燒(shao)損,燒(shao)損后將(jiang)導致電(dian)(dian)弧電(dian)(dian)壓增高,直(zhi)接(jie)影響熔池保護效果(guo),也會使焊(han)(han)(han)縫氧化,甚至產生焊(han)(han)(han)縫寬度(du)不(bu)均(jun)的缺陷。

h. 鎢極伸出長度

鎢(wu)極伸出長度(du)指(zhi)鎢(wu)極超出噴嘴端面的長度(du)。鎢(wu)極伸出的短,可(ke)以使噴嘴與焊件相對靠(kao)近(jin),氣體保護效果好,通(tong)常鎢(wu)極伸出長度(du)為2~8mm。

i. 噴嘴(nozzle)

常(chang)用鎢極(ji)氬弧(hu)焊用噴(pen)(pen)(pen)(pen)(pen)嘴(zui)結(jie)構如圖4-37所示,D端與焊槍(qiang)連接段為(wei)(wei)(wei)長(chang)10~12mm的(de)(de)圓柱體(ti);小圓柱的(de)(de)末端部(bu)分的(de)(de)長(chang)度(du)L不(bu)應小于噴(pen)(pen)(pen)(pen)(pen)嘴(zui)孔徑,其長(chang)度(du)以(yi)1.2~1.5倍噴(pen)(pen)(pen)(pen)(pen)嘴(zui)孔內徑(d)為(wei)(wei)(wei)宜(yi)。噴(pen)(pen)(pen)(pen)(pen)嘴(zui)的(de)(de)錐形部(bu)分有緩沖氣(qi)(qi)(qi)流的(de)(de)作用,可改善(shan)保(bao)(bao)護(hu)(hu)效(xiao)果(guo)。為(wei)(wei)(wei)了(le)提高(gao)氣(qi)(qi)(qi)體(ti)保(bao)(bao)護(hu)(hu)效(xiao)果(guo),噴(pen)(pen)(pen)(pen)(pen)嘴(zui)的(de)(de)內壁應光(guang)滑、不(bu)允許有棱(leng)角、凹槽(cao),不(bu)得沾上飛(fei)濺物。為(wei)(wei)(wei)了(le)使氬氣(qi)(qi)(qi)從噴(pen)(pen)(pen)(pen)(pen)嘴(zui)噴(pen)(pen)(pen)(pen)(pen)出(chu)時成為(wei)(wei)(wei)穩定(ding)的(de)(de)層流,提高(gao)氣(qi)(qi)(qi)體(ti)保(bao)(bao)護(hu)(hu)效(xiao)果(guo),焊槍(qiang)應有氣(qi)(qi)(qi)體(ti)透(tou)鏡(類似穩定(ding)裝(zhuang)置(zhi))、多孔性(xing)擋板(可用1~2層銅絲網(wang)組(zu)成,網(wang)目(mu)數不(bu)得少于600~700孔/c㎡)及緩沖室。氣(qi)(qi)(qi)體(ti)流量(liang)不(bu)變,增大噴(pen)(pen)(pen)(pen)(pen)嘴(zui)內徑時,氣(qi)(qi)(qi)體(ti)挺度(du)下降,對(dui)熔池保(bao)(bao)護(hu)(hu)減弱;氣(qi)(qi)(qi)體(ti)流量(liang)不(bu)變,噴(pen)(pen)(pen)(pen)(pen)嘴(zui)內徑變小時,氣(qi)(qi)(qi)體(ti)的(de)(de)流速增加(jia)過(guo)多,可造(zao)成氣(qi)(qi)(qi)體(ti)紊流,也會(hui)造(zao)成保(bao)(bao)護(hu)(hu)效(xiao)果(guo)不(bu)好。實踐證明,在(zai)手工(gong)鎢極(ji)氬弧(hu)焊時,噴(pen)(pen)(pen)(pen)(pen)嘴(zui)內徑在(zai)8~20mm 范圍內,氣(qi)(qi)(qi)體(ti)流量(liang)以(yi)10~25L/min為(wei)(wei)(wei)宜(yi)。當(dang)噴(pen)(pen)(pen)(pen)(pen)嘴(zui)和(he)氣(qi)(qi)(qi)體(ti)流量(liang)一(yi)定(ding)時,噴(pen)(pen)(pen)(pen)(pen)嘴(zui)至焊件(jian)之間的(de)(de)距離愈短(duan),則保(bao)(bao)護(hu)(hu)效(xiao)果(guo)愈好,但過(guo)小會(hui)影響焊工(gong)的(de)(de)視線和(he)引起鎢極(ji)與焊件(jian)短(duan)路(lu)。對(dui)于噴(pen)(pen)(pen)(pen)(pen)嘴(zui)內徑為(wei)(wei)(wei)8~20mm的(de)(de)噴(pen)(pen)(pen)(pen)(pen)嘴(zui),距離焊件(jian)一(yi)般不(bu)超(chao)過(guo)15mm。

j. 焊接電流、噴(pen)嘴直(zhi)徑和保護氣(qi)體流量對應關系

焊(han)接電流、噴嘴(zui)直徑和(he)保護氣體流量對應關系見表4-29。

k. 冷卻水流量

焊(han)槍(qiang)額定電流大于160A時(shi),焊(han)接前焊(han)槍(qiang)須通冷卻(que)水,焊(han)接完成須滯后停止(zhi)冷卻(que)水。冷卻(que)水流量不得小于1L/min,否則焊(han)機(ji)無法啟動或易燒毀(hui)焊(han)槍(qiang)。

4. 提高氣(qi)體保(bao)護(hu)效果的(de)措施

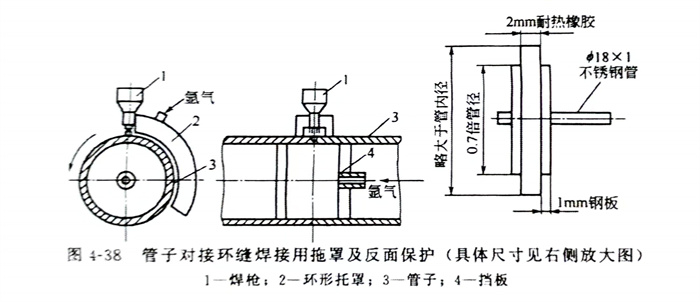

為(wei)了使焊接(jie)接(jie)頭正面和背(bei)面得到可靠保護,可采用圖4-38~圖4-40所示(shi)的工藝(yi)裝備來提高保護效果(guo)。

5. 操(cao)作技術

裝(zhuang)配定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han),應采用與正式焊(han)(han)(han)(han)(han)(han)接(jie)相同的(de)(de)(de)焊(han)(han)(han)(han)(han)(han)絲和工(gong)藝,定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han)縫的(de)(de)(de)長(chang)度(du)(du)距離應根據焊(han)(han)(han)(han)(han)(han)件(jian)厚(hou)度(du)(du)與結構剛度(du)(du)而定(ding)(ding)(ding)(ding)(ding)。一般每段(duan)定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han)縫長(chang)度(du)(du)為(wei)5~15mm,焊(han)(han)(han)(han)(han)(han)縫厚(hou)度(du)(du)不大(da)于2mm。例如直徑φ60mm以下的(de)(de)(de)不銹鋼管(guan)(guan)子(zi)(zi),用定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han)點固(gu)定(ding)(ding)(ding)(ding)(ding)2~3處(chu),定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han)縫長(chang)度(du)(du)約(yue)5mm。直徑159mm的(de)(de)(de)不銹鋼管(guan)(guan)子(zi)(zi),用定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han)點固(gu)定(ding)(ding)(ding)(ding)(ding)4處(chu),定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han)縫長(chang)度(du)(du)約(yue)10mm。定(ding)(ding)(ding)(ding)(ding)位(wei)焊(han)(han)(han)(han)(han)(han)縫須保證質量,不允(yun)許存(cun)在焊(han)(han)(han)(han)(han)(han)接(jie)缺陷。對(dui)接(jie)焊(han)(han)(han)(han)(han)(han)時,焊(han)(han)(han)(han)(han)(han)槍與焊(han)(han)(han)(han)(han)(han)件(jian)之間保持后傾(qing),鎢極與焊(han)(han)(han)(han)(han)(han)件(jian)之間傾(qing)角為(wei)75°~80°,填充焊(han)(han)(han)(han)(han)(han)絲與焊(han)(han)(han)(han)(han)(han)件(jian)傾(qing)角為(wei)75°~15°,希望填充焊(han)(han)(han)(han)(han)(han)絲與焊(han)(han)(han)(han)(han)(han)件(jian)傾(qing)角越(yue)小越(yue)好,過(guo)大(da)則容易擾亂氣體保護(hu);角接(jie)焊(han)(han)(han)(han)(han)(han)時,除(chu)了對(dui)接(jie)焊(han)(han)(han)(han)(han)(han)的(de)(de)(de)要(yao)求外,還(huan)要(yao)求與板之間的(de)(de)(de)相對(dui)位(wei)置。

填充焊(han)(han)(han)絲(si)時動作要緩、穩,不要破壞氬氣(qi)(qi)對熔(rong)池的(de)保(bao)護。不能(neng)像氣(qi)(qi)焊(han)(han)(han)那樣在熔(rong)池中攪(jiao)拌,應一(yi)滴(di)一(yi)滴(di)地緩慢送入熔(rong)池,或者將焊(han)(han)(han)絲(si)端頭(tou)浸入熔(rong)池中不斷填入,并(bing)向前移動,焊(han)(han)(han)絲(si)端頭(tou)不能(neng)脫離氣(qi)(qi)體保(bao)護區。要防止焊(han)(han)(han)絲(si)與鎢極(ji)接(jie)觸、碰撞,否則加(jia)劇鎢極(ji)燒損,而引起焊(han)(han)(han)縫夾鎢。焊(han)(han)(han)接(jie)收弧時、應減慢焊(han)(han)(han)接(jie)速度、增加(jia)焊(han)(han)(han)絲(si)填充量。焊(han)(han)(han)接(jie)薄板(ban)時,為了(le)防止變(bian)形可(ke)采用銅襯(chen)墊(dian),并(bing)將焊(han)(han)(han)件壓貼(tie)于(yu)襯(chen)墊(dian)上,以利于(yu)散熱。在銅墊(dian)板(ban)上加(jia)工出凹槽(cao),凹槽(cao)對準(zhun)焊(han)(han)(han)縫以便背面(mian)充氬氣(qi)(qi)保(bao)護,見圖4-39、圖4-40。電弧熄滅后,焊(han)(han)(han)槍(qiang)噴嘴仍須對準(zhun)熔(rong)池,以延長氬氣(qi)(qi)保(bao)護效(xiao)果(guo)。

實踐證明,從焊(han)接(jie)接(jie)頭(tou)的顏色,也可以判斷焊(han)接(jie)區的保護效(xiao)果,詳見表(biao)4-32。

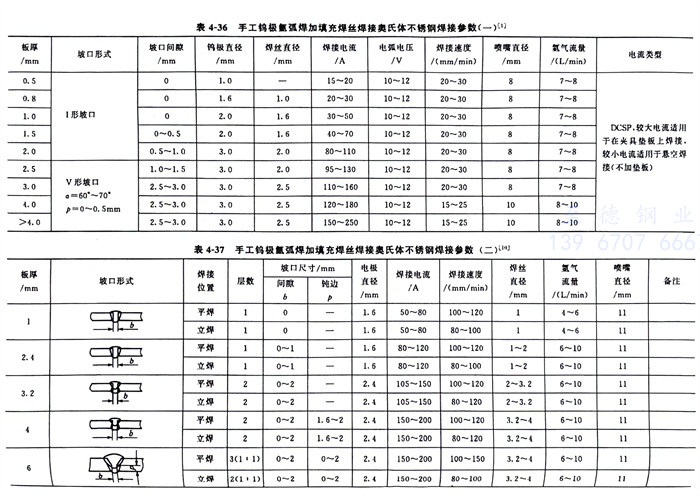

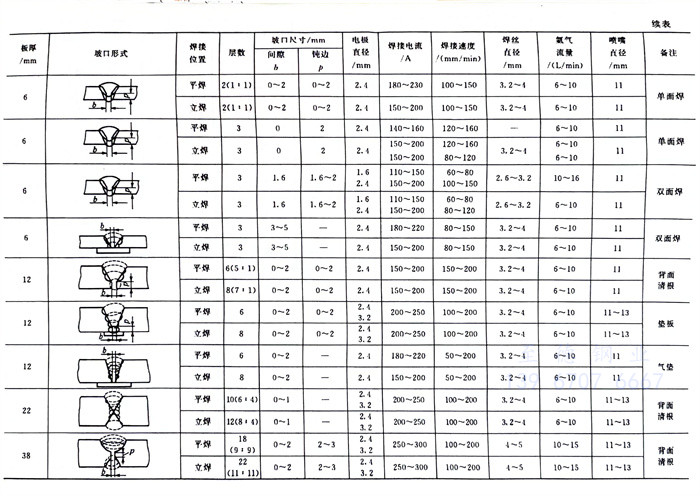

機械操作不(bu)加(jia)填充焊(han)(han)(han)絲(si)(si)的(de)鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)焊(han)(han)(han)接(jie)(jie)工(gong)藝(yi)參數(shu),見(jian)(jian)表(biao)(biao)4-33;機械操作加(jia)填充焊(han)(han)(han)絲(si)(si)的(de)鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)焊(han)(han)(han)接(jie)(jie)工(gong)藝(yi)參數(shu),見(jian)(jian)表(biao)(biao)4-34;鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)加(jia)填充焊(han)(han)(han)絲(si)(si)焊(han)(han)(han)接(jie)(jie)薄板奧氏體不(bu)銹鋼焊(han)(han)(han)接(jie)(jie)參數(shu),見(jian)(jian)表(biao)(biao)4-35;手工(gong)鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)加(jia)填充焊(han)(han)(han)絲(si)(si)的(de)焊(han)(han)(han)接(jie)(jie)參數(shu),見(jian)(jian)表(biao)(biao)4-36~表(biao)(biao)4-38,奧氏體不(bu)銹鋼管鎢(wu)(wu)極氬(ya)(ya)弧焊(han)(han)(han)焊(han)(han)(han)接(jie)(jie)參數(shu),見(jian)(jian)表(biao)(biao)4-39。