為保證不銹鋼無縫管整個圓柱范圍內的缺陷檢測,需要不銹鋼管與探頭之間做相對螺旋運動。探頭靜止不動,不銹鋼無縫鋼管螺旋前進是相對較為簡單的檢測方式,該檢測機構在國內出現的歷史較長,優勢與劣勢都非常明顯。主要優點在于設備結構簡單,成本較低,缺點在于檢測速度較慢,通常情況下可靠的檢測直線速度不超過3m/min,對產量不高的單位較為適合。

不銹鋼(gang)無縫管螺旋(xuan)前進(jin)自(zi)動探(tan)傷系(xi)統通常情(qing)況下包括上料(liao)機(ji)構(gou)、鋼(gang)管螺旋(xuan)前進(jin)機(ji)構(gou)、檢測(ce)水槽機(ji)構(gou)、下料(liao)與分揀機(ji)構(gou)、電(dian)氣控制機(ji)構(gou)、超聲探(tan)傷儀器(qi)等。

1. 上料(liao)機構

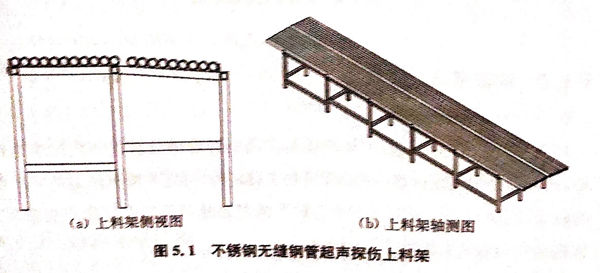

上料(liao)(liao)(liao)(liao)(liao)機(ji)(ji)構(gou)的(de)主要(yao)功能是實現不銹鋼管(guan)(guan)自(zi)動進入鋼管(guan)(guan)螺旋前進輥(gun)道(dao)。在工(gong)程生產中(zhong),上料(liao)(liao)(liao)(liao)(liao)機(ji)(ji)構(gou)可以有多種方式,最常見(jian)的(de)結構(gou)方式為開放式斜坡料(liao)(liao)(liao)(liao)(liao)架(jia)配合鋼管(guan)(guan)下料(liao)(liao)(liao)(liao)(liao)機(ji)(ji)構(gou),其中(zhong)上料(liao)(liao)(liao)(liao)(liao)架(jia)如圖5.1所示(shi),料(liao)(liao)(liao)(liao)(liao)架(jia)長度(du)與(yu)檢測單(dan)位鋼管(guan)(guan)最長長度(du)相適應,寬度(du)可依據實際檢測空間設計,料(liao)(liao)(liao)(liao)(liao)架(jia)一般采(cai)用金(jin)屬管(guan)(guan)焊接(jie)而成,表面(mian)防銹處理(li)并(bing)按照車間設備要(yao)求噴涂合適色(se)彩,料(liao)(liao)(liao)(liao)(liao)架(jia)與(yu)鋼管(guan)(guan)接(jie)觸部表面(mian)均包覆有非金(jin)屬材(cai)料(liao)(liao)(liao)(liao)(liao),防止鋼管(guan)(guan)表面(mian)劃傷。

探(tan)傷(shang)前(qian),操作人員將(jiang)不(bu)銹鋼(gang)無(wu)縫鋼(gang)管(guan)(guan)(guan)(guan)整齊(qi)排(pai)放至上(shang)(shang)料(liao)(liao)架(jia)上(shang)(shang),上(shang)(shang)料(liao)(liao)架(jia)前(qian)后兩側均布(bu)置有鋼(gang)管(guan)(guan)(guan)(guan)擋料(liao)(liao)板(ban),防(fang)止鋼(gang)管(guan)(guan)(guan)(guan)從料(liao)(liao)架(jia)上(shang)(shang)滾(gun)(gun)落,其(qi)中傾斜面側擋料(liao)(liao)板(ban)的(de)(de)主(zhu)要作用是防(fang)止不(bu)銹鋼(gang)管(guan)(guan)(guan)(guan)在重(zhong)(zhong)力的(de)(de)作用下(xia)無(wu)序下(xia)滑滾(gun)(gun)動(dong)進(jin)入(ru)鋼(gang)管(guan)(guan)(guan)(guan)前(qian)進(jin)輥(gun)道。自動(dong)探(tan)傷(shang)時,當需要鋼(gang)管(guan)(guan)(guan)(guan)進(jin)人前(qian)進(jin)輥(gun)道,可通過鋼(gang)管(guan)(guan)(guan)(guan)下(xia)料(liao)(liao)機構將(jiang)一根鋼(gang)管(guan)(guan)(guan)(guan)送(song)人指定位置,比(bi)較(jiao)典型的(de)(de)上(shang)(shang)料(liao)(liao)機構可采用氣缸驅動(dong)一傾斜板(ban)將(jiang)一根鋼(gang)管(guan)(guan)(guan)(guan)頂起(qi),鋼(gang)管(guan)(guan)(guan)(guan)利用自身重(zhong)(zhong)力滾(gun)(gun)人前(qian)進(jin)輥(gun)道。

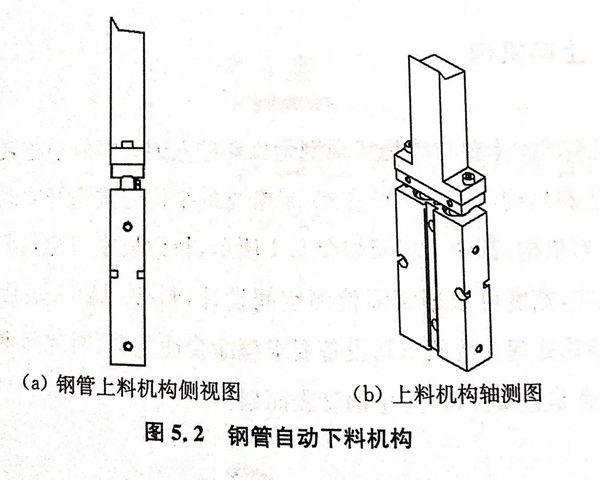

如圖5.2所示,氣(qi)(qi)缸(gang)與非金屬材料制成的上料塊左側為尖凸(tu),當(dang)氣(qi)(qi)缸(gang)升起(qi)時(shi),可從緊排鋼管的間(jian)隙(xi)內插入,將最外側鋼管與整(zheng)排鋼管分離(li)(li),鋼管在尖凸(tu)側邊的傾斜邊上通過(guo)自身重(zhong)力(li)滾動下滑,進人鋼管檢測前(qian)進輥道。在整(zheng)個料架長度方向安裝若干套下料機(ji)構,氣(qi)(qi)缸(gang)同時(shi)動作,保證鋼管順利分離(li)(li)。

2. 鋼管(guan)螺旋前進機構

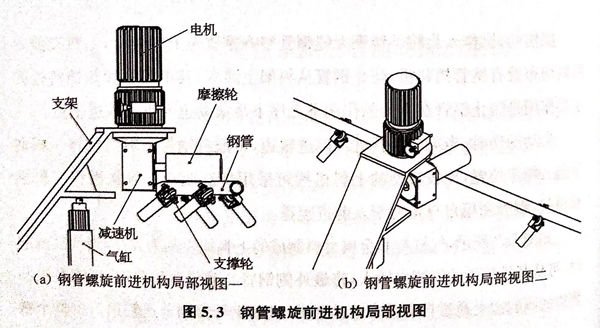

不(bu)銹鋼管螺旋(xuan)前(qian)進(jin)機構的(de)主(zhu)要功(gong)能是實現(xian)鋼管沿軸(zhou)線前(qian)進(jin)的(de)同時快(kuai)速(su)旋(xuan)轉(zhuan),該部分是螺旋(xuan)前(qian)進(jin)超(chao)聲探(tan)傷系統的(de)關鍵機構,對(dui)超(chao)聲檢(jian)測的(de)最終結果影響較大,調整(zheng)不(bu)適合的(de)情況(kuang)下還(huan)會對(dui)不(bu)銹鋼無縫鋼管的(de)直線度產生破(po)壞。該機構的(de)局部示意(yi)圖如圖5.3所示。

圖(tu)5.3中,鋼(gang)(gang)(gang)管(guan)(guan)螺旋(xuan)運動(dong)(dong)(dong)的(de)(de)驅動(dong)(dong)(dong)源為異步(bu)電動(dong)(dong)(dong)機,該(gai)電機通(tong)(tong)過減(jian)速機與摩擦(ca)(ca)(ca)輪相連接,摩擦(ca)(ca)(ca)輪旋(xuan)轉(zhuan)(zhuan)(zhuan)軸線與不銹鋼(gang)(gang)(gang)管(guan)(guan)軸線成(cheng)一(yi)定(ding)夾(jia)角(jiao)α,該(gai)角(jiao)度固定(ding)不可(ke)調(diao)(diao),摩擦(ca)(ca)(ca)輪轉(zhuan)(zhuan)(zhuan)動(dong)(dong)(dong)時,通(tong)(tong)過摩擦(ca)(ca)(ca)力帶動(dong)(dong)(dong)鋼(gang)(gang)(gang)管(guan)(guan)螺旋(xuan)運動(dong)(dong)(dong),摩擦(ca)(ca)(ca)輪的(de)(de)材(cai)(cai)質(zhi)應選(xuan)擇摩擦(ca)(ca)(ca)系(xi)數較大的(de)(de)非(fei)金屬材(cai)(cai)料以防止(zhi)對(dui)(dui)(dui)鋼(gang)(gang)(gang)管(guan)(guan)表面造成(cheng)磨損(sun),同時還要兼顧耐(nai)磨性從而保證(zheng)摩擦(ca)(ca)(ca)輪的(de)(de)工作(zuo)壽命(ming)。鋼(gang)(gang)(gang)管(guan)(guan)底部有成(cheng)對(dui)(dui)(dui)交叉(cha)布置(zhi)的(de)(de)支(zhi)撐輪,每個支(zhi)撐輪的(de)(de)轉(zhuan)(zhuan)(zhuan)動(dong)(dong)(dong)軸方(fang)向可(ke)調(diao)(diao),與鋼(gang)(gang)(gang)管(guan)(guan)軸線成(cheng)一(yi)定(ding)夾(jia)角(jiao)β,通(tong)(tong)過調(diao)(diao)整β的(de)(de)大小可(ke)以改變(bian)鋼(gang)(gang)(gang)管(guan)(guan)運動(dong)(dong)(dong)的(de)(de)螺距大小;調(diao)(diao)整交叉(cha)支(zhi)撐輪之間(jian)的(de)(de)間(jian)隙可(ke)實現鋼(gang)(gang)(gang)管(guan)(guan)高度的(de)(de)調(diao)(diao)整,滿足(zu)檢測不同直徑的(de)(de)鋼(gang)(gang)(gang)管(guan)(guan),支(zhi)撐輪的(de)(de)材(cai)(cai)質(zhi)應選(xuan)擇非(fei)金屬材(cai)(cai)料,主要目的(de)(de)還是(shi)要防止(zhi)對(dui)(dui)(dui)鋼(gang)(gang)(gang)管(guan)(guan)表面造成(cheng)磨損(sun),一(yi)般情況下選(xuan)擇尼龍材(cai)(cai)料即可(ke)滿足(zu)要求。在整個鋼(gang)(gang)(gang)管(guan)(guan)螺旋(xuan)前(qian)進輥(gun)道(dao)上均勻布置(zhi)幾套驅動(dong)(dong)(dong)裝置(zhi),每套驅動(dong)(dong)(dong)裝置(zhi)兩(liang)側(ce)均有成(cheng)對(dui)(dui)(dui)交叉(cha)支(zhi)撐輪,交叉(cha)支(zhi)撐輪間(jian)距越(yue)小越(yue)有利于保證(zheng)鋼(gang)(gang)(gang)管(guan)(guan)的(de)(de)直線度,這種(zhong)作(zuo)用對(dui)(dui)(dui)小徑鋼(gang)(gang)(gang)管(guan)(guan)尤其明顯。

整個(ge)異(yi)步電機(ji)驅動裝(zhuang)置(zhi)固定在可(ke)轉(zhuan)(zhuan)動支(zhi)(zhi)架上,直(zhi)動氣缸(gang)升起(qi)時(shi)(shi)頂起(qi)可(ke)轉(zhuan)(zhuan)動支(zhi)(zhi)架上的平板(ban),異(yi)步電機(ji)驅動裝(zhuang)置(zhi)隨支(zhi)(zhi)架一起(qi)動作(zuo)脫離與不銹鋼(gang)管接觸位置(zhi),此時(shi)(shi)可(ke)完成鋼(gang)管自動上料,當鋼(gang)管進(jin)入輥道后,氣缸(gang)退回,可(ke)轉(zhuan)(zhuan)動支(zhi)(zhi)架在自身重力作(zuo)用下跟隨氣缸(gang)平穩(wen)進(jin)入工作(zuo)位置(zhi),保證摩擦輪與鋼(gang)管接觸。

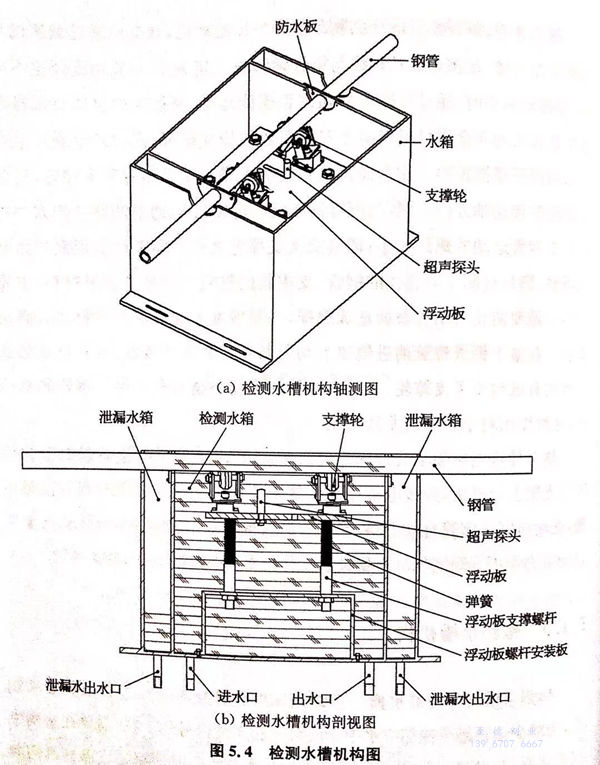

3. 檢測水槽機構

檢測(ce)(ce)水(shui)(shui)(shui)(shui)(shui)(shui)槽(cao)又稱局(ju)部水(shui)(shui)(shui)(shui)(shui)(shui)槽(cao)。不銹鋼(gang)(gang)無縫鋼(gang)(gang)管(guan)(guan)超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)探(tan)(tan)(tan)傷(shang)過程(cheng)中(zhong)需要水(shui)(shui)(shui)(shui)(shui)(shui)耦(ou)合(he),為(wei)(wei)減少鋼(gang)(gang)管(guan)(guan)超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)探(tan)(tan)(tan)傷(shang)時(shi)水(shui)(shui)(shui)(shui)(shui)(shui)中(zhong)雜(za)質對(dui)檢測(ce)(ce)聲(sheng)(sheng)(sheng)(sheng)波(bo)信號的(de)干(gan)擾,需要在(zai)(zai)(zai)水(shui)(shui)(shui)(shui)(shui)(shui)槽(cao)中(zhong)通循環水(shui)(shui)(shui)(shui)(shui)(shui),及時(shi)將鋼(gang)(gang)管(guan)(guan)表面或外部進入水(shui)(shui)(shui)(shui)(shui)(shui)槽(cao)中(zhong)的(de)雜(za)質帶離。該部分(fen)機(ji)構如圖5.4所(suo)(suo)示。如圖所(suo)(suo)示,整個水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)分(fen)割為(wei)(wei)三部分(fen),中(zhong)間部分(fen)為(wei)(wei)耦(ou)合(he)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang),下端帶有進水(shui)(shui)(shui)(shui)(shui)(shui)口(kou)和出水(shui)(shui)(shui)(shui)(shui)(shui)口(kou),兩(liang)(liang)側(ce)為(wei)(wei)泄(xie)(xie)漏(lou)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang),鋼(gang)(gang)管(guan)(guan)穿過的(de)時(shi)候,耦(ou)合(he)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)里的(de)水(shui)(shui)(shui)(shui)(shui)(shui)會向兩(liang)(liang)邊(bian)泄(xie)(xie)漏(lou),泄(xie)(xie)漏(lou)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)底部也開有出水(shui)(shui)(shui)(shui)(shui)(shui)口(kou),保證(zheng)泄(xie)(xie)漏(lou)水(shui)(shui)(shui)(shui)(shui)(shui)及時(shi)回流至(zhi)水(shui)(shui)(shui)(shui)(shui)(shui)源箱(xiang)。中(zhong)間耦(ou)合(he)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)中(zhong)安(an)裝(zhuang)有超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)探(tan)(tan)(tan)頭(tou)、鋼(gang)(gang)管(guan)(guan)交叉布置的(de)兩(liang)(liang)套支撐輪(lun),所(suo)(suo)有這(zhe)些部件全部安(an)裝(zhuang)在(zai)(zai)(zai)一(yi)塊(kuai)浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)上(shang),浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)在(zai)(zai)(zai)四(si)(si)個角上(shang)開有通孔(kong)(kong),與(yu)四(si)(si)根雙頭(tou)螺(luo)桿間隙(xi)合(he),螺(luo)桿下部與(yu)安(an)裝(zhuang)于(yu)水(shui)(shui)(shui)(shui)(shui)(shui)箱(xiang)底部的(de)固定板(ban)(ban)固定在(zai)(zai)(zai)一(yi)起(qi),螺(luo)桿上(shang)部套有壓縮彈簧(huang),浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)及板(ban)(ban)上(shang)安(an)裝(zhuang)的(de)部件重量(liang)由四(si)(si)根壓縮彈簧(huang)共同承受,當浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)受驅動(dong)(dong)(dong)(dong)(dong)(dong)力的(de)時(shi)候,可(ke)隨力的(de)方向在(zai)(zai)(zai)一(yi)定范圍內運動(dong)(dong)(dong)(dong)(dong)(dong),如圖5.4b所(suo)(suo)示。采用浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)安(an)裝(zhuang)的(de)主要原因是(shi)鋼(gang)(gang)管(guan)(guan)螺(luo)旋前(qian)進時(shi)會產(chan)生抖(dou)(dou)(dou)動(dong)(dong)(dong)(dong)(dong)(dong),安(an)裝(zhuang)在(zai)(zai)(zai)浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)上(shang)支撐輪(lun)與(yu)鋼(gang)(gang)管(guan)(guan)緊密貼合(he)跟隨鋼(gang)(gang)管(guan)(guan)抖(dou)(dou)(dou)動(dong)(dong)(dong)(dong)(dong)(dong)并限制鋼(gang)(gang)管(guan)(guan)動(dong)(dong)(dong)(dong)(dong)(dong)作幅度,進而帶動(dong)(dong)(dong)(dong)(dong)(dong)浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)抖(dou)(dou)(dou)動(dong)(dong)(dong)(dong)(dong)(dong),超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)探(tan)(tan)(tan)頭(tou)安(an)裝(zhuang)在(zai)(zai)(zai)浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)上(shang)一(yi)起(qi)抖(dou)(dou)(dou)動(dong)(dong)(dong)(dong)(dong)(dong),因此超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)探(tan)(tan)(tan)頭(tou)與(yu)鋼(gang)(gang)管(guan)(guan)的(de)相對(dui)位置不會發(fa)生大(da)的(de)變化(hua)(hua),從而保證(zheng)了超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)檢測(ce)(ce)的(de)參數一(yi)致性。浮(fu)(fu)(fu)動(dong)(dong)(dong)(dong)(dong)(dong)板(ban)(ban)上(shang)開有腰槽(cao)孔(kong)(kong),用來安(an)裝(zhuang)和調整超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)探(tan)(tan)(tan)頭(tou),當檢測(ce)(ce)鋼(gang)(gang)管(guan)(guan)直徑(jing)發(fa)生變化(hua)(hua)后(hou),可(ke)通過腰槽(cao)孔(kong)(kong)調整超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)探(tan)(tan)(tan)頭(tou)的(de)偏(pian)移距離,滿(man)足超(chao)(chao)(chao)聲(sheng)(sheng)(sheng)(sheng)橫波(bo)探(tan)(tan)(tan)傷(shang)的(de)檢測(ce)(ce)條件。

向耦合水(shui)(shui)(shui)(shui)(shui)(shui)槽中供水(shui)(shui)(shui)(shui)(shui)(shui)時,可采(cai)用小功(gong)率水(shui)(shui)(shui)(shui)(shui)(shui)泵,同時在(zai)各(ge)個進水(shui)(shui)(shui)(shui)(shui)(shui)口(kou)與出水(shui)(shui)(shui)(shui)(shui)(shui)口(kou)安裝(zhuang)水(shui)(shui)(shui)(shui)(shui)(shui)流(liu)調(diao)節閥,控(kong)制(zhi)進水(shui)(shui)(shui)(shui)(shui)(shui)和排水(shui)(shui)(shui)(shui)(shui)(shui)的速度,既保(bao)(bao)(bao)證耦合水(shui)(shui)(shui)(shui)(shui)(shui)漫(man)過待檢測(ce)(ce)(ce)鋼管(guan)的超聲人射區域,同時又(you)保(bao)(bao)(bao)證水(shui)(shui)(shui)(shui)(shui)(shui)面(mian)高度不發生大的變化。在(zai)工(gong)程檢測(ce)(ce)(ce)過程中,經常采(cai)用不銹鋼儲(chu)水(shui)(shui)(shui)(shui)(shui)(shui)箱作為超聲檢測(ce)(ce)(ce)耦合水(shui)(shui)(shui)(shui)(shui)(shui)源,水(shui)(shui)(shui)(shui)(shui)(shui)泵抽水(shui)(shui)(shui)(shui)(shui)(shui)口(kou)安裝(zhuang)過濾網,防止儲(chu)水(shui)(shui)(shui)(shui)(shui)(shui)箱中的雜(za)質進入耦合水(shui)(shui)(shui)(shui)(shui)(shui)槽。盡管(guan)如此,儲(chu)水(shui)(shui)(shui)(shui)(shui)(shui)箱中的水(shui)(shui)(shui)(shui)(shui)(shui)源還需要定期更換,以保(bao)(bao)(bao)證檢測(ce)(ce)(ce)耦合水(shui)(shui)(shui)(shui)(shui)(shui)源的品質。

4. 下料與(yu)分(fen)揀機構

下料機(ji)構(gou)原理上可采(cai)用上料機(ji)構(gou)相同的結構(gou),只是(shi)落(luo)料斜板的尺(chi)寸與形狀有所差異,因此在該節中將不再對下料機(ji)構(gou)描述。

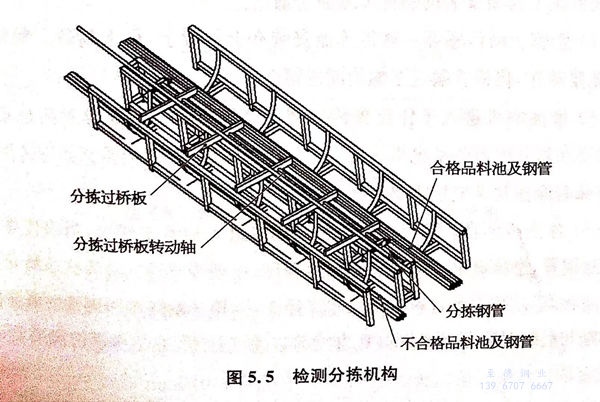

分(fen)揀(jian)機構作為不銹(xiu)鋼管(guan)超聲(sheng)探傷(shang)系統的重要(yao)組(zu)成部分(fen),主要(yao)功能是將檢(jian)測(ce)不合格(ge)產品(pin)與合格(ge)產品(pin)分(fen)別存放,避免(mian)混(hun)料。

分揀(jian)(jian)(jian)機構主要(yao)由合格(ge)(ge)品(pin)(pin)料(liao)(liao)(liao)(liao)池(chi)(chi)、不(bu)合格(ge)(ge)料(liao)(liao)(liao)(liao)池(chi)(chi)、分揀(jian)(jian)(jian)過橋(qiao)(qiao)(qiao)(qiao)機構組成(cheng),局部如圖5.5所示。整個分揀(jian)(jian)(jian)機構的(de)長度應與(yu)檢測單位鋼(gang)(gang)(gang)管(guan)的(de)長度相(xiang)匹(pi)配,寬度根據生產效(xiao)率確定。因不(bu)合格(ge)(ge)品(pin)(pin)數(shu)量較少,故合格(ge)(ge)品(pin)(pin)料(liao)(liao)(liao)(liao)池(chi)(chi)容量較不(bu)合格(ge)(ge)品(pin)(pin)料(liao)(liao)(liao)(liao)池(chi)(chi)大,兩個料(liao)(liao)(liao)(liao)池(chi)(chi)承接鋼(gang)(gang)(gang)管(guan)的(de)主要(yao)部件是與(yu)料(liao)(liao)(liao)(liao)架焊(han)接在(zai)一起(qi)的(de)U型(xing)扁(bian)鋼(gang)(gang)(gang),與(yu)鋼(gang)(gang)(gang)管(guan)接觸的(de)表面均(jun)包覆非(fei)金屬材料(liao)(liao)(liao)(liao)。鋼(gang)(gang)(gang)管(guan)分揀(jian)(jian)(jian)時(shi)進(jin)入(ru)(ru)合格(ge)(ge)品(pin)(pin)料(liao)(liao)(liao)(liao)池(chi)(chi)或(huo)(huo)者不(bu)合格(ge)(ge)品(pin)(pin)料(liao)(liao)(liao)(liao)池(chi)(chi)主要(yao)依靠分揀(jian)(jian)(jian)過橋(qiao)(qiao)(qiao)(qiao)板。當鋼(gang)(gang)(gang)管(guan)存在(zai)缺陷時(shi),分揀(jian)(jian)(jian)過橋(qiao)(qiao)(qiao)(qiao)板轉(zhuan)(zhuan)動(dong)軸順時(shi)針轉(zhuan)(zhuan)動(dong),帶動(dong)分揀(jian)(jian)(jian)過橋(qiao)(qiao)(qiao)(qiao)板前(qian)端升(sheng)起(qi),下(xia)料(liao)(liao)(liao)(liao)機構輸送(song)鋼(gang)(gang)(gang)管(guan)掉入(ru)(ru)不(bu)合格(ge)(ge)品(pin)(pin)料(liao)(liao)(liao)(liao)池(chi)(chi);如果鋼(gang)(gang)(gang)管(guan)不(bu)存在(zai)缺陷,則分揀(jian)(jian)(jian)過橋(qiao)(qiao)(qiao)(qiao)板轉(zhuan)(zhuan)動(dong)軸靜止(zhi)不(bu)動(dong),下(xia)料(liao)(liao)(liao)(liao)機構輸送(song)鋼(gang)(gang)(gang)管(guan)通(tong)過分揀(jian)(jian)(jian)過橋(qiao)(qiao)(qiao)(qiao)板落入(ru)(ru)合格(ge)(ge)品(pin)(pin)料(liao)(liao)(liao)(liao)池(chi)(chi)。分揀(jian)(jian)(jian)過橋(qiao)(qiao)(qiao)(qiao)板轉(zhuan)(zhuan)動(dong)軸兩端采用(yong)軸承支撐,利用(yong)氣缸或(huo)(huo)電機驅動(dong)轉(zhuan)(zhuan)動(dong)軸轉(zhuan)(zhuan)動(dong)。

5. 電(dian)氣控(kong)制機構

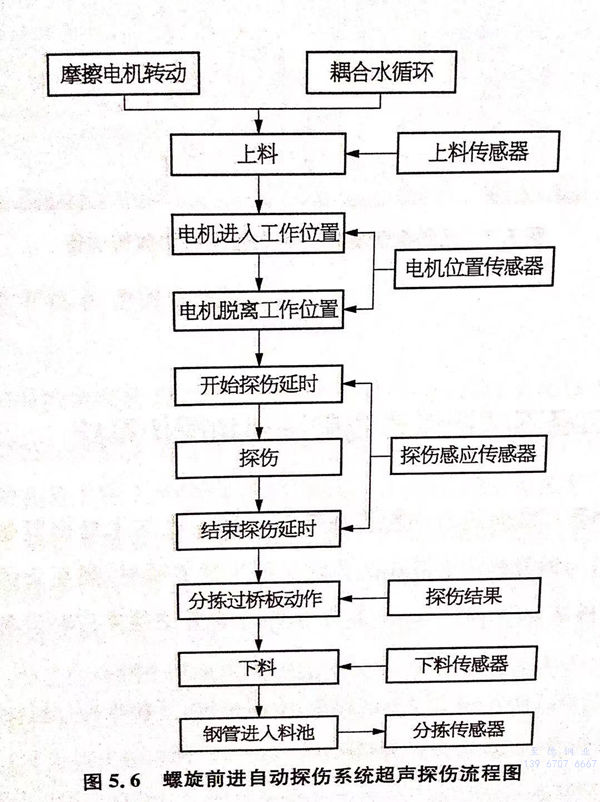

電(dian)氣控制機(ji)構(gou)是超(chao)聲探傷(shang)(shang)設備的重要(yao)(yao)組成(cheng)部分,關系(xi)(xi)到整套系(xi)(xi)統的動作(zuo)是否協調,進(jin)而(er)影響不(bu)銹(xiu)鋼(gang)(gang)管(guan)(guan)的超(chao)聲探傷(shang)(shang)結果及分揀(jian)是否準確等。電(dian)氣控制機(ji)構(gou)的主要(yao)(yao)功能包(bao)括:鋼(gang)(gang)管(guan)(guan)自(zi)動上料(liao);摩擦(ca)驅動電(dian)機(ji)運轉,實現不(bu)銹(xiu)鋼(gang)(gang)管(guan)(guan)的螺旋前進(jin);檢測水槽耦合水的循(xun)環;不(bu)銹(xiu)鋼(gang)(gang)管(guan)(guan)探傷(shang)(shang)的開始與結束;鋼(gang)(gang)管(guan)(guan)分揀(jian)與下料(liao)。

上述(shu)功(gong)能的實現(xian)主要(yao)依靠(kao)傳感器的感應以及與(yu)超(chao)聲探傷儀的通訊。整套檢(jian)測系統上需要(yao)安裝的感應傳感器包括:

a. 鋼(gang)管上料傳(chuan)感(gan)器(qi)

該(gai)傳感器(qi)安裝在上(shang)料(liao)架上(shang),用來判斷(duan)上(shang)料(liao)機(ji)構是否需要動作,將鋼管輸送(song)至(zhi)螺(luo)旋前進輥(gun)道。

b. 摩(mo)擦電機進入工作位置(zhi)傳(chuan)感(gan)器

該傳感(gan)器安裝在螺旋前進輥(gun)道上,需要在每套摩擦(ca)驅(qu)動電機(ji)裝置(zhi)對應的(de)輥(gun)道位(wei)(wei)置(zhi)安裝,當傳感(gan)器感(gan)應到鋼管,意味著摩擦(ca)驅(qu)動電機(ji)需要進人工(gong)作位(wei)(wei)置(zhi)。

c. 探傷傳感器

該(gai)傳感(gan)器(qi)安裝在鋼(gang)(gang)管(guan)進(jin)人檢(jian)測水槽(cao)前,當該(gai)傳感(gan)器(qi)感(gan)應(ying)到鋼(gang)(gang)管(guan),意味(wei)(wei)著鋼(gang)(gang)管(guan)即將開(kai)始超聲(sheng)探(tan)(tan)傷(shang)(shang),當該(gai)傳感(gan)器(qi)從感(gan)應(ying)狀態跳變(bian)到無感(gan)應(ying)狀態,意味(wei)(wei)著鋼(gang)(gang)管(guan)即將結束超聲(sheng)探(tan)(tan)傷(shang)(shang),鋼(gang)(gang)管(guan)開(kai)始探(tan)(tan)傷(shang)(shang)和鋼(gang)(gang)管(guan)結束探(tan)(tan)傷(shang)(shang)的(de)前延與后延時間可以根據鋼(gang)(gang)管(guan)直線前進(jin)速度(du)計算,在超聲(sheng)探(tan)(tan)傷(shang)(shang)儀(yi)或PLC中設定。

d. 鋼(gang)管下料(liao)傳感器

該傳(chuan)感(gan)(gan)器安裝在螺旋前進輥道末端(duan),當傳(chuan)感(gan)(gan)器感(gan)(gan)應到鋼管,意味著下料(liao)機構(gou)需要動作,輸(shu)送鋼管進人合格品(pin)料(liao)池或(huo)不合格品(pin)料(liao)池。

e. 鋼管(guan)分揀傳感器(qi)

該類型傳感器共(gong)需(xu)2套,分別(bie)安(an)裝在(zai)合(he)格(ge)品料(liao)池(chi)與不合(he)格(ge)品料(liao)池(chi)適當(dang)位置,用(yong)來感應鋼(gang)管(guan)(guan)是(shi)否已經進入(ru)料(liao)池(chi)。不銹鋼(gang)無縫(feng)管(guan)(guan)螺旋(xuan)前進自動探(tan)傷系統(tong)的超(chao)聲探(tan)傷流程圖(tu)如圖(tu)5.6所(suo)示。

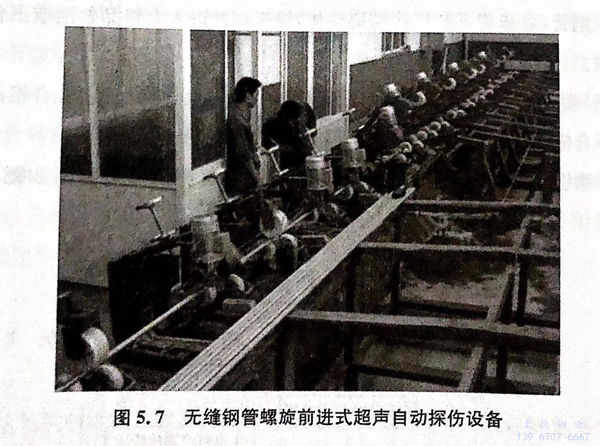

圖5.7是上海某汽車零部件公(gong)(gong)司使用(yong)的不銹(xiu)鋼無縫鋼管(guan)螺旋前進(jin)式(shi)超聲(sheng)自動探傷設備。該設備檢(jian)測速度3m/min,適應不銹(xiu)鋼管(guan)外(wai)徑$6mm~φ40mm,缺陷分辨率遠超GB/T 5777-2008要求(qiu),達到不銹(xiu)鋼管(guan)內(nei)外(wai)壁縱向、橫向人工缺陷5mm×0.15mm×0.1mm(長×寬(kuan)×深),滿(man)足德國博世公(gong)(gong)司的產(chan)品質量(liang)控制要求(qiu),鋼管(guan)段(duan)部盲(mang)區(qu)≤150mm。